The smallest parts often carry the greatest weight in modern innovation. Their flawless function is essential across high-stakes industries like aerospace, medical, and electronics.

Small parts machining doesn’t always get the spotlight—but it should. From the aerospace industry to cutting-edge medical devices, the smallest components often carry the biggest responsibility. These pieces might be no larger than a grain of rice, yet they must perform flawlessly under intense conditions.

At Eagle Metalcraft, we specialize in this high-stakes world—delivering micro-precision parts with consistency, speed, and zero compromise.

What Exactly Is Small Parts Machining?

Behind every flawless miniature component is a complex process rooted in extreme precision. This discipline combines advanced tools with deep expertise in materials and tolerances.

Precision on a Micro Scale

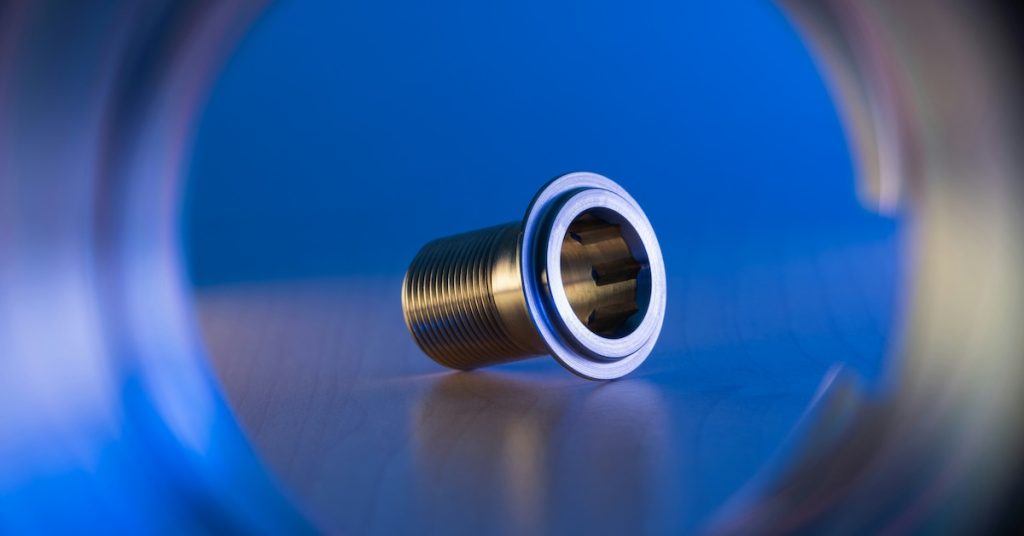

Small parts machining refers to the detailed manufacturing of compact metal or plastic components. These parts typically feature intricate geometries, demand tight tolerances, and rely on specialized tooling such as custom collets.

Specialized Tools and Methods

The process often involves:

- CNC machining using high-speed spindles

- Multi-axis setups for complex parts

- Micromachining tools for sub-millimeter features

Whether it’s a surgical screw or a tiny aerospace connector, the common thread is precision.

Why Small Doesn’t Mean Simple

Just because a part is small doesn’t mean it’s easier to make. It’s often the opposite.

The Challenges of Miniature Manufacturing

Microscale machining introduces unique challenges such as tool deflection, heat buildup, chip control, and surface finish requirements. At such a small scale, even the slightest vibration or inconsistency can throw off the entire process.

What It Takes to Get It Right

Success in this field demands a deep understanding of material behavior, machine dynamics, and tool wear. Engineers must also account for design for manufacturability (DFM) early on, ensuring the part is not only functional but practical to produce at scale.

CNC Machining Services Built for Precision

We’ve built our capabilities around the unique demands of small parts. Whether you need five pieces or five thousand, we offer precision with flexibility.

Our Capabilities

Our facility is optimized for high-performance CNC machining of small parts. We offer:

- Turning and milling for parts under 1 inch in diameter

- Micro-drilling and micro-tapping

- Custom fixturing and collets for delicate work

- Prototype or production runs

- Full inspection reports and traceability

Your Trusted Local Partner

When engineers search for “machine shops near me” that handle complex, compact parts, we’re the name they trust, even if they’re outside of the Syracuse area.

Industries We Support

From spacecraft to surgical suites, our parts show up where performance is non-negotiable. We serve sectors where precision is crucial:

Diverse, Demanding Applications

We partner with innovators across industries that demand precision without compromise:

- Aerospace: Lightweight fasteners, sensor housings

- Medical: Bone screws, micro-tools, surgical guides

- Defense: Firing pins, electronics casings

- Electronics: Connectors, heat sinks, miniature brackets

Consistent Quality Every Time

All our parts meet ISO-certified standards and are backed by rigorous quality control and a culture of continuous improvement.

Skilled Hands Behind the Machines

Even the best technology needs human talent. Our machinists blend technical knowledge with artisan-level craftsmanship.

The Human Side of High-Tech

CNC machinist jobs are more than a career—they’re a craft. Especially in small parts machining, precision isn’t optional.

Growing with Eagle Metalcraft

At Eagle Metalcraft, we offer:

- A modern, collaborative shop environment

- Advanced equipment and technology

- Training and growth opportunities

If you’re detail-oriented and love working with your hands, this might just be the career path for you.

Why Eagle Metalcraft?

There’s a reason engineers and manufacturers across the country trust us. Our history, capability, and responsiveness make us a powerful extension of your team.

What Sets Us Apart

With over 70 years of machining excellence, we bring both legacy knowledge and modern innovation to every project. Here’s what sets us apart:

- Lights-out machining for 24/7 production

- Industry 4.0 systems for real-time traceability

- In-house prototyping and tooling design

- Rapid response and fast lead times

- A passion for helping our clients innovate

Let’s Build Something Precise

Have a small parts machining project in mind? Whether you’re prototyping or scaling up, we’re here to help. Reach out to Eagle Metalcraft to get started—and see how precision can transform your next design.

FAQs About Small Parts Machining

Have questions about small parts machining? You’re not alone. Here are some of the most common things our clients want to know before starting a project.

What materials can be used in small parts machining?

We work with a wide range of metals and plastics, including stainless steel, titanium, aluminum, brass, and engineered polymers. Material selection depends on your application’s mechanical, thermal, and biocompatibility requirements.

How precise can your CNC machines get?

Our machines regularly hold tolerances within ±0.0002 inches. With specialized tooling and inspection equipment, we ensure consistent precision for even the most intricate geometries.

Do you handle both prototyping and full production?

Yes, we support both. Whether you need a handful of prototypes or thousands of production parts, we scale with your needs, delivering accuracy and repeatability every step of the way.

Can you help with part design or DFM (design for manufacturability)?

Absolutely. Our engineers offer in-house design support and can assist with optimizing your part for both function and manufacturability. This helps reduce cost, improve performance, and shorten lead times.

How do I get started?

Simply contact us with your drawings, models, or even just an idea. We’ll review your project, provide a quote, and guide you through the next steps.