Yes, it’s true, precision-engineered CNC milling parts can improve manufacturing efficiency, product quality, and supply chain reliability for your business.

In manufacturing, precision isn’t just a nice-to-have; it’s the foundation of product quality and operational efficiency. The right CNC milling parts ensure every cut, groove, and hole meets exact specifications. A single out-of-tolerance component can cause assembly line delays, rejected batches, or even product recalls.

For manufacturers in aerospace, automotive, electronics, and medical devices, the stakes are high. Precision CNC milling parts not only maintain product integrity but also protect your reputation and bottom line.

Why Precision CNC Milling Machine Parts Matter in Modern Manufacturing

Precision isn’t optional in competitive industries; the right CNC milling parts ensure your products meet exact specifications, reduce costly errors, and keep production lines running smoothly.

In competitive markets, the smallest error can lead to huge losses. CNC milling parts help manufacturers maintain consistency across production runs, achieve tighter tolerances, and reduce waste. In industries like aerospace and medical devices, these benefits are mission-critical.

Common CNC Milling Parts and Their Applications

Knowing the essential components of a CNC milling machine helps you source the right parts for your specific manufacturing needs.

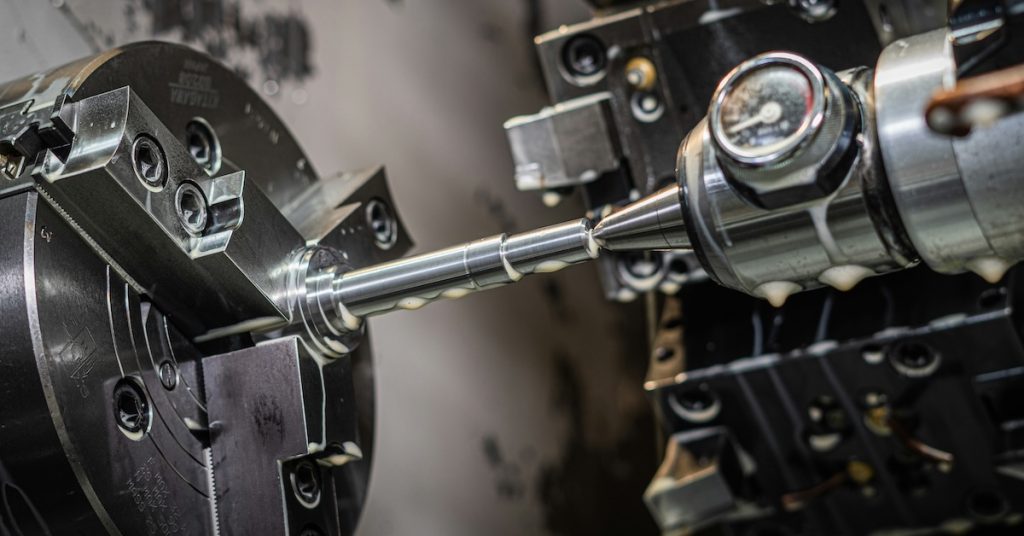

CNC milling machines rely on several core parts to function effectively:

- Spindles – The heart of the milling process, providing rotation for cutting.

- Fixtures and workholding devices – Secure raw materials for precision work.

- Cutting tools – Designed for materials like aluminum, stainless steel, or titanium.

- Slides and guides – Ensure smooth, accurate tool movement.

Different industries have unique requirements. For instance, aerospace parts demand strength-to-weight optimization, while electronics require micron-level accuracy.

Industry Use Cases for CNC Milling

From aerospace to electronics, CNC milling adapts to industry-specific challenges with unmatched precision and reliability.

CNC milling manufacturers serve a wide variety of sectors

CNC milling technology is versatile enough to meet the exacting demands of multiple industries, adapting to different materials, tolerances, and performance requirements. Let’s take a look at the sectors below.

Aerospace

Lightweight aluminum and titanium parts for aircraft structures and engines.

Automotive

Engine blocks, transmission housings, and safety-critical brackets.

Electronics

Heat sinks, housings, and small intricate parts for devices.

Medical Devices

Surgical tools, implants, and components with ultra-high tolerances.

Choosing the Right CNC Milling Parts Manufacturer

The wrong supplier can cost you more than money; it can cost you time, customers, and credibility.

When selecting a manufacturer, consider:

- Proven quality control with CMM inspections

- ISO 9001 or AS9100 certification

- Reliable lead times with urgent order capacity

- Transparent material sourcing and traceability

A low-cost supplier without proper quality processes can lead to expensive rework and production delays.

Custom CNC Milling For Unique Requirements

Custom parts can be the difference between an adequate product and a market-leading solution.

Benefits of custom CNC milling machining include:

- Exact match to design specifications.

- Reduced assembly complexity.

- Enhanced performance through optimized geometry and materials.

One robotics company solved frequent part failures by switching to a custom titanium housing, tripling part lifespan and cutting maintenance costs.

From Prototype to Production: CNC Machining Services

The best CNC partners guide you from concept to mass production without sacrificing quality.

Key stages of machining include:

- Prototyping – Test designs before committing to production.

- Small batch runs – Ideal for pilot projects.

- Mass production – Scaled manufacturing with consistent results.

This flexibility helps companies respond quickly to market demands while maintaining standards.

Material Options for CNC Milling

The right material choice impacts performance, durability, and cost.

Popular materials include:

- Aluminum – Lightweight, corrosion-resistant.

- Stainless Steel – Strong, wear-resistant.

- Titanium – Exceptional strength-to-weight ratio.

- Plastics – Affordable and versatile for non-structural components.

Partner with a Trusted CNC Milling Parts Supplier

Choosing the right partner ensures quality, reliability, and long-term savings.

At Eagle Metalcraft, we provide precision parts, custom components, and full machining services with competitive lead times. We serve industries ranging from aerospace to industrial automation, and we pride ourselves on delivering consistent quality.

FAQs

Here are answers to the most common questions we receive from manufacturing managers and engineers about CNC milling parts, their applications, and sourcing best practices.

What are the parts of a CNC milling machine?

The main parts include the spindle, cutting tools, workholding fixtures, machine bed, and control system. Each plays a critical role in precision and efficiency.

How do custom CNC milling parts save costs?

Custom parts can reduce assembly steps, extend part lifespan, and improve overall performance, lowering the total cost of ownership over time.

What tolerances can CNC milling achieve?

High-quality CNC machining can reach tolerances as tight as ±0.005mm, depending on material, part complexity, and equipment capabilities.

How fast can I get CNC milling parts delivered?

Lead times vary by project. Rapid prototypes can be delivered in a few days, while large-scale production typically takes several weeks.