In the dynamic world of precision sheet metal fabrication, staying competitive means staying ahead of the curve. At Eagle Metalcraft, we embrace advanced manufacturing technologies not just as tools, but as strategic investments that enhance efficiency, precision, and overall product quality. These innovations—from powerful lasers to robotics—are transforming how we approach every job, delivering better outcomes for our customers across a range of industries.

Advanced manufacturing encompasses a variety of high-tech systems and techniques that streamline operations, reduce errors, and enable greater scalability. With each upgrade, Eagle Metalcraft strengthens its ability to produce complex components faster, with tighter tolerances and less waste. The result is a smarter, more agile fabrication environment built to meet modern manufacturing demands.

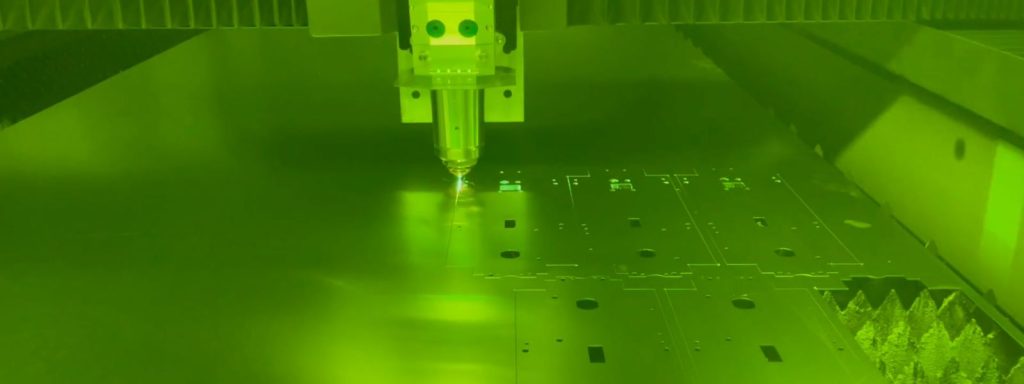

Introducing the LVD 6KW PUMA 3015 Laser

One of the most notable investments in our technological evolution is the LVD 6KW PUMA 3015 Laser, a state-of-the-art machine that reOne of our most impactful technology upgrades is the LVD 6KW PUMA 3015 Laser. This powerful, fiber-optic laser machine delivers ultra-precise, high-speed cutting for a wide variety of materials and thicknesses. By investing in this equipment, Eagle Metalcraft has dramatically improved cut quality, reduced scrap rates, and enhanced overall production efficiency.

Key Capabilities of the PUMA 3015

- Available in 3, 6, or 12-kW power options for versatile cutting applications

- Seamlessly integrates with automation systems for high-volume production

- Industry 4.0–ready for smart factory data integration and performance tracking

- Automated loading and unloading reduce downtime and manual handling

- Supports lights-out operation for overnight, unattended runs

- Quadruples cutting capacity, allowing faster project completion

Since acquiring the PUMA 3015 in July, we’ve seen measurable improvements in speed, cost control, and throughput across our shop floor.

Additional Investments in Fabrication Technology

Over the past year, Eagle Metalcraft has invested over $1 million in capital equipment, reinforcing our commitment to cutting-edge capabilities and world-class service. These investments support our mission to provide precision solutions that meet the evolving needs of modern manufacturing.

CNC Machining

Our upgraded CNC machining systems now feature:

- Additional axes for handling intricate, multi-surface parts

- Higher spindle speeds for reduced cycle times

- Smarter tool-changing systems to support uninterrupted workflows

These upgrades allow for greater design freedom and faster turnaround in the production of high-precision components.

Robotic Automation

Automation has transformed how we approach fabrication by:

- Streamlining material handling to improve safety and reduce fatigue

- Enhancing welding and assembly consistency through robotic precision

- Minimizing downtime and rework to boost operational efficiency

From prototyping to production, robotics allows us to maintain a high standard of quality while optimizing labor and time.

Key Benefits of Advanced Manufacturing Technologies

The adoption of advanced technologies like the PUMA laser and CNC automation offers a wide range of benefits that extend through every stage of fabrication. These advantages help Eagle Metalcraft deliver faster, smarter, and more cost-effective results for our clients.

Enhanced Cutting Precision

With laser systems like the PUMA 3015, we achieve extremely tight tolerances and razor-sharp edge quality, even on complex or delicate parts. This level of precision reduces the need for secondary finishing processes, cuts down on scrap, and ensures every part meets the customer’s exact specifications the first time.

The result is greater consistency across production runs and higher customer satisfaction. Whether we’re working on intricate electrical housings or structural aerospace panels, the ability to hold tight tolerances gives us and our clients a critical competitive advantage.

Increased Production Speed

Automation and high-powered equipment significantly reduce setup and processing times. Instead of relying on multiple machines or manual steps, we’re able to cut, form, and assemble parts in a streamlined flow that accelerates every project. For customers, this means faster lead times, quicker market launches, and less time spent waiting for prototypes or parts to arrive.

Whether it’s a one-off job or a recurring production run, speed is a major differentiator—and we’ve built our infrastructure to deliver on that expectation.

Workflow Efficiency

The integration of smart equipment, automation, and digital controls allows for more efficient planning, scheduling, and execution. Jobs move seamlessly between workstations, and operators receive real-time alerts for maintenance or process adjustments.

By minimizing downtime and reducing human error, we maximize throughput while keeping quality at the forefront. Our team is empowered to focus more on innovation and problem-solving, rather than routine or repetitive tasks.

Versatile Material Handling

Modern machines like the PUMA 3015 are capable of cutting a wide range of metals, including stainless steel, carbon steel, and aluminum, at various thicknesses. This versatility is critical in industries like medical, defense, and aerospace, where material specifications vary widely depending on function and regulatory requirements.

Our team can transition quickly between material types and projects without extensive retooling or setup, keeping our production nimble and adaptable.

Cost Efficiency

By reducing rework, improving accuracy, and enabling lights-out operation, our advanced technologies help drive significant cost savings. Less waste, fewer labor hours, and shorter cycle times all contribute to a lower total cost of ownership for every part we produce. These savings allow us to offer competitive pricing while maintaining the high standards our clients expect.

The long-term ROI of our equipment investments is seen not only in production performance but also in reduced maintenance, energy usage, and supply chain overhead.

Smart Factory Capabilities

With Industry 4.0 connectivity built into our systems, we can monitor machine performance, predict failures before they happen, and adjust workflows based on real-time data. This allows us to operate more proactively, optimizing everything from machine uptime to staffing. These capabilities also improve transparency for our clients, who benefit from more predictable timelines and measurable performance tracking.

Improved Shop Floor Safety

Automation has also improved working conditions by reducing the need for repetitive motion, heavy lifting, and manual operation of hazardous equipment. This creates a safer, more ergonomic environment for our team members and supports our commitment to workplace well-being. When paired with our in-house safety protocols and certifications, these systems contribute to a culture of continuous improvement and risk reduction.

Looking Ahead: The Future Of Precision Fabrication

At Eagle Metalcraft, our focus on advanced manufacturing isn’t just about staying current—it’s about setting the standard. Every technology we implement is chosen with one goal in mind: to deliver better, faster, and more scalable fabrication services to our clients. From the integration of high-speed laser systems to the expansion of robotic workflows, our facility is designed to adapt and grow with the needs of the modern manufacturing landscape.

As we continue to evolve with emerging trends and technologies, our focus remains on:

- Accelerating lead times

- Improving part consistency and tolerance

- Lowering costs without sacrificing quality

- Expanding capabilities to serve new markets and industries

By continually upgrading our equipment and embracing smart manufacturing principles, we empower our customers with fast, accurate, and scalable custom fabrication solutions.

FAQs

At Eagle Metalcraft, advanced manufacturing isn’t just a buzzword; it’s a business strategy. From the acquisition of high-powered lasers to the implementation of robotic systems and Industry 4.0 integration, every investment we make is designed to enhance speed, accuracy, and efficiency. This FAQ outlines how our advanced manufacturing technologies support our clients’ success and position us as a forward-thinking leader in precision sheet metal fabrication.

What is advanced manufacturing?

Advanced manufacturing refers to the use of innovative technologies—like robotics, fiber lasers, and data-connected systems—to streamline production, improve quality, and reduce costs. It allows manufacturers to deliver high-precision components faster, with fewer errors and greater scalability.

What are the key capabilities of the LVD PUMA 3015 Laser?

- Cuts a wide range of materials at high speeds

- Quadruple cutting capacity

- Supports 24/7 lights-out operation

- Integrates with automation and Industry 4.0 platforms

- Reduces waste and improves edge quality

How does automation benefit the fabrication process?

Automation reduces manual handling, increases repeatability, and shortens lead times. It also improves workplace safety, reduces fatigue, and enables lights-out production, helping us complete jobs faster without sacrificing quality.

What are the benefits of robotic welding and part handling?

Robotic systems offer unmatched consistency, precision, and speed. They minimize human error, streamline assembly, and allow for higher production volumes while maintaining tight tolerances.

How does advanced equipment improve cut quality and tolerances?

Machines like the PUMA 3015 produce razor-sharp, accurate cuts that often eliminate the need for secondary finishing. This improves part consistency and lowers production costs by reducing rework and scrap.

How do advanced systems reduce lead times?

With automation and high-powered equipment, we minimize manual steps and streamline processes. That means faster turnarounds for prototypes, small-batch orders, and large production runs alike.

What impact do these upgrades have on cost efficiency?

Advanced manufacturing reduces waste, labor hours, and energy consumption. The result is a lower total cost of ownership for parts, allowing us to offer competitive pricing without compromising quality.

How do these technologies contribute to workplace safety?

Automation reduces repetitive motion and the need for manual operation of potentially hazardous equipment. Combined with our safety protocols, this creates a more ergonomic, risk-reduced environment for our team.