A Game-Changer in Welding Technology

Eagle Metalcraft to Revolutionize Production with Cutting-Edge Robotic Welding Laser

In a groundbreaking move to boost efficiency and cater to burgeoning customer demands, Eagle Metalcraft, a prominent sheet metal manufacturer in Central New York, has made a significant investment in cutting-edge Robotic Laser Welding technology. This not only represents a major milestone for the company but also establishes a new benchmark in the industry, as Eagle Metalcraft pioneers the deployment of such advanced capabilities in the region.

In a groundbreaking move to boost efficiency and cater to burgeoning customer demands, Eagle Metalcraft, a prominent sheet metal manufacturer in Central New York, has made a significant investment in cutting-edge Robotic Laser Welding technology. This not only represents a major milestone for the company but also establishes a new benchmark in the industry, as Eagle Metalcraft pioneers the deployment of such advanced capabilities in the region.

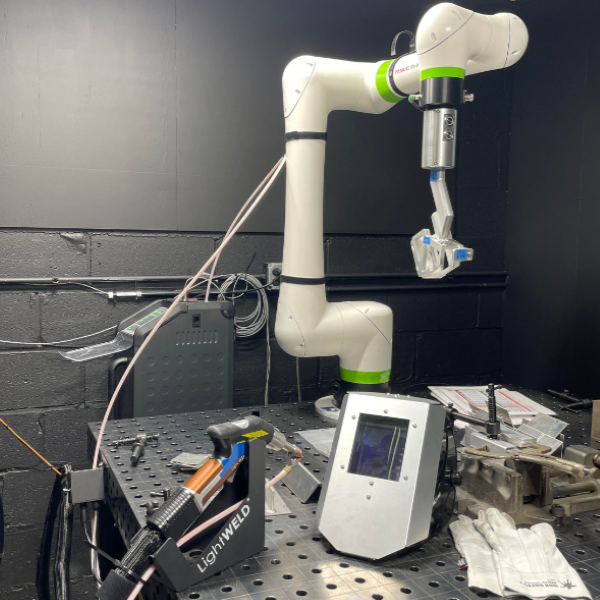

The cornerstone of this technological leap is the installation of a Robotic Laser Welding Cell, aptly named LWC-1. Known as a cell, the entire system is equipped with a cutting-edge collaborative robotic, a laser welder, a programming area, and a power source. LWC-1 promises to revolutionize the welding process by offering unparalleled speed, consistency, and quality.

One of the new system’s most remarkable features is its ability to weld at speeds up to eight times faster than traditional TIG welding methods. This significant increase in efficiency translates to shorter lead times and quicker turnaround for customer orders.

“We were facing a bottleneck in our traditional welding processes,” said Michael Bower, owner of Eagle Metalcraft. “This pivotal challenge led us to invest in cutting-edge technology that will enhance our efficiency and accelerate our order fulfillment.”

Prioritizing Safety in Every Detail

Safety has been a paramount concern in the meticulous design and implementation of the LWC-1. Recognizing the potential risks posed by intense welding light, Eagle Metalcraft has implemented rigorous measures to protect the health and safety of its workforce and visitors.

Unlike conventional welding lights, which can be uncomfortable to look at without eye protection, the laser welding light does not induce discomfort. It’s akin to observing a solar eclipse—it doesn’t cause immediate discomfort, yet it poses a significant risk to eye health if viewed without proper protection. In fact, it can damage the eyes from a distance of two football fields away! This comparison is important to understand the potential risks associated with the technology and the need for proper safety measures.

For this reason, the room housing the welding cell has been meticulously constructed with black metal and concrete walls painted black. This design choice effectively absorbs the blinding light emitted by the welding machine, providing a secure environment for personnel within the facility.

Eagle Metalcraft has also installed a protective viewing window, allowing observers to witness the machine in operation safely without risk. By prioritizing safety at every stage of the process, Eagle Metalcraft ensures that both its workforce and visitors can interact with the technology confidently and securely.

Embracing Future-Ready Manufacturing

The integration of the LWC-1 into Eagle Metalcraft’s operations is just one element of a larger three-phase capital project to modernize and enhance production capabilities.

With each phase of the capital project, Eagle Metalcraft inches closer to realizing its vision of a streamlined, future-ready manufacturing facility equipped to tackle future challenges. As the company continues integrating cutting-edge technologies and refining its production processes, customers can benefit from enhanced reliability, flexibility, and responsiveness. By staying at the forefront of innovation, Eagle Metalcraft reaffirms its position as a trusted partner for clients seeking uncompromising quality and precision in sheet metal manufacturing.

About Eagle Metalcraft

Founded in 1953 as Eagle Manufacturing Company, Jack Helmer and his sons developed Eagle Metalcraft into what it is today. In 2022, Michael Bower acquired the company to carry on the legacy of quality work in sheet metal, machining, welding, powder coating, and finishing artwork.

Michael has since made strategic improvements to the company, including achieving Service-Disabled Veteran Owned Small Business certification, which creates more contract opportunities. Additionally, Michael was named the 2023 Veteran Owned Small Business Entrepreneur of the Year for upstate New York.

As the premier sheet metal fabricator, Eagle Metalcraft can amplify your brand. Our one-stop solution combines precision sheet metal fabrication with vibrant powder coating and custom silk screening to create durable, high-quality components delivered on time, every time. Experience seamless craftsmanship and exceptional customer service with Eagle Metalcraft – where precision meets excellence. We look forward to teaming up with you. Contact us today!