Bringing a new product to life starts with an idea, but turning that idea into a tangible, functional part requires precision, planning, and the right fabrication partner. In the world of custom manufacturing, sheet metal prototyping plays a critical role in bridging the gap between initial concept and full-scale production.

Whether you’re developing a bracket for aerospace, a housing for medical equipment, or a structural component for industrial use, prototyping allows engineers to validate fit, function, and form before committing to large production runs.

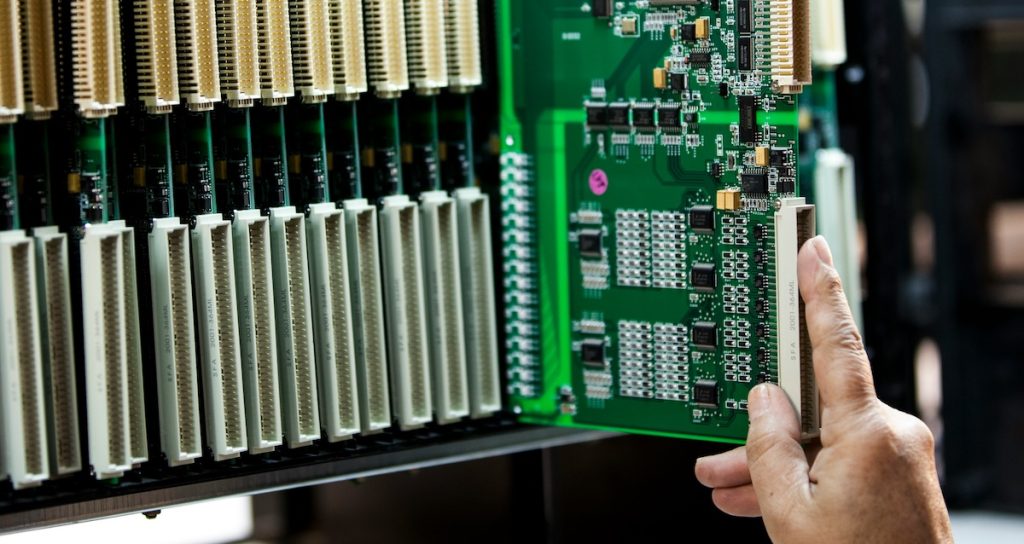

At Eagle Metalcraft, we specialize in transforming digital designs into real-world prototypes with speed and accuracy. By combining advanced CAD modeling, CNC forming, laser cutting, and hands-on engineering expertise, we help clients iterate quickly and refine designs without compromising on quality.

This guide walks through the full sheet metal prototyping process—from your first sketch to a ready-for-production part—so you can move forward with confidence.

Why Sheet Metal Prototypes Are Critical in Modern Manufacturing

Sheet metal prototypes provide the opportunity to test structural integrity, material behavior, and manufacturability before committing to large-scale production. They’re especially valuable for regulated industries like aerospace, medical, and defense, where part failure is not an option.

- Accelerates design validation and approvals

- Reduces the risk of defects in final production

- Enables functional testing under real-world conditions

- Supports faster time-to-market

Key Characteristics of a Successful Sheet Metal Prototype

The success of any sheet metal prototype hinges on precision, turnaround speed, and manufacturability. These attributes define whether a prototype will accurately represent the final product, and whether it can scale.

Tight Tolerances & Repeatability

A prototype must match the final product’s geometry within strict tolerances, often within ±0.005 inches. Eagle Metalcraft specializes in precision metal fabrication that ensures repeatability from prototype to production.

Material Behavior in Prototyping

Choosing the right metal—aluminum, stainless steel, copper, or titanium—is essential during prototyping. Eagle Metalcraft’s wide materials selection allows engineers to simulate and test how metals behave during forming, bending, and machining.

Design-to-Fabrication Alignment

Effective prototyping requires strong collaboration between design and manufacturing. Eagle Metalcraft’s engineering and prototyping services ensure your CAD files translate into accurate, testable components.

Common Techniques for Sheet Metal Prototypes

Multiple forming and fabrication methods are used in prototyping to match both design intent and production feasibility.

Laser Cutting

Ideal for creating clean, precise outlines from sheet stock, laser cutting enables fast iteration of designs. Eagle Metalcraft’s laser cutting services provide tight kerf control and superior edge quality.

CNC Machining

When prototypes require drilled holes, complex cutouts, or tapped features, CNC machining ensures accuracy. Eagle Metalcraft offers 3-axis and 4-axis CNC machining for advanced geometries.

CNC Press Brake Bending

Prototype enclosures, brackets, and flanges are formed using CNC press brakes. Eagle’s sheet metal forming processes ensure bends are consistent, repeatable, and angle-perfect.

Spot Welding and Assembly

Prototypes often include welded joints or spot welds to test full assemblies. Eagle’s fabrication capabilities cover forming, joining, and post-processing.

Benefits of Rapid Sheet Metal Prototyping

Fast, functional sheet metal prototypes give design engineers the flexibility to iterate and optimize quickly without investing in expensive tooling.

- Faster design cycles: Rapid iteration shortens development from weeks to days

- Cost-effective: No need for hard tooling or dies

- Scalable: A good prototype can scale directly into production

- Real-world testing: Validate weight, fit, rigidity, and thermal performance

Design Considerations for Sheet Metal Prototypes

To ensure a successful prototype, several design and manufacturability factors must be addressed early.

DFM (Design for Manufacturability)

Designing with manufacturing constraints in mind—from bend radii to hole spacing—can prevent rework. Eagle Metalcraft’s team assists with prototyping and design refinement.

CAD Model Optimization

Clean geometry, correct tolerances, and realistic material callouts help ensure a seamless translation to fabrication. Eagle Metalcraft supports most major CAD formats and ensures rapid CNC programming.

Assembly Fit and Tolerance Stack-Up

Prototypes for assemblies must account for cumulative tolerance to ensure all components fit as intended. Eagle Metalcraft verifies fit through our robust quality assurance processes.

Industries That Rely on Sheet Metal Prototypes

Let’s take a look at the industries that really rely on sheet metal fabrication.

Aerospace & Avionics

In aviation, form and weight are critical. Eagle Metalcraft provides lightweight aerospace sheet metal components that are prototype-tested for performance and reliability.

Medical Device Development

Medical prototypes require biocompatibility and precise enclosures for electronics or sensors. Eagle’s medical prototyping supports sterile-grade materials like 316 stainless steel.

Defense & Tactical Equipment

Military-grade prototypes must be rugged and tested under stress. Eagle Metalcraft’s defense fabrication enables performance validation before entering field use.

High-End Electronics

Prototyping for electronic enclosures demands EMI shielding, thermal performance, and cosmetic perfection. Eagle delivers custom fabrication that aligns with electronic housing needs.

Why Choose Eagle Metalcraft for Your Sheet Metal Prototype

With over 70 years of experience, Eagle Metalcraft is uniquely positioned to deliver high-precision prototypes with speed, accuracy, and engineering support.

In-House Engineering

Collaborate directly with engineers during the design and fabrication phases to avoid costly errors. Explore Eagle Metalcraft’s engineering support for custom projects.

Full-Service Fabrication

From laser cutting and machining to finishing and assembly, Eagle offers vertically integrated fabrication services that take your prototype from concept to completion.

ISO-Certified Quality

Eagle Metalcraft is ISO 9001 certified, ensuring consistency and traceability in every prototype and production run.

Bring your designs to life faster

As speed and precision continue to drive innovation, sheet metal prototyping will remain vital in reducing time-to-market and refining final product quality. With experienced partners like Eagle Metalcraft, you can bring your designs to life faster, with confidence that they’ll scale seamlessly into production.

FAQs: Is Sheet Metal Prototyping Right For Your Company?

Have questions about sheet metal prototyping? Below are answers to some of the most common inquiries we receive about software, materials, lead times, and design support.

What software should I use for sheet metal prototyping?

Popular options include SolidWorks, Autodesk Fusion 360, and Inventor. These platforms offer dedicated sheet metal features like bend reliefs, flat pattern creation, and DFM checks to ensure your part can be manufactured efficiently.

Can you help me design my sheet metal prototype?

Yes, we can assist with design modifications, tolerancing, and optimizing your part for manufacturability, especially for bending, cutting, and assembly.

How fast can I get a sheet metal prototype?

Turnaround times vary, but simple prototypes can often be delivered in as little as 3–7 business days depending on material availability and complexity.

What materials are available for prototyping?

Common materials include aluminum, cold-rolled steel, stainless steel, and galvanized steel. Specialty metals are available upon request.

Do prototypes include surface finishing?

Prototypes can include basic deburring and cleaning. Additional finishes like powder coating or anodizing are available if needed.

Will my prototype match production quality?

Yes, we use the same industrial equipment and tolerances for prototyping as we do for full production runs to ensure consistency.