Designing for laser cutting isn’t just about aesthetics or geometry; it’s about precision, cost, and how smoothly your parts flow through the shop.

At Eagle Metalcraft, we see firsthand how thoughtful laser cutting design can make or break a production run. Whether you’re a product designer, engineer, or manufacturer, this guide will help you avoid costly mistakes and get beautifully cut metal parts the first time.

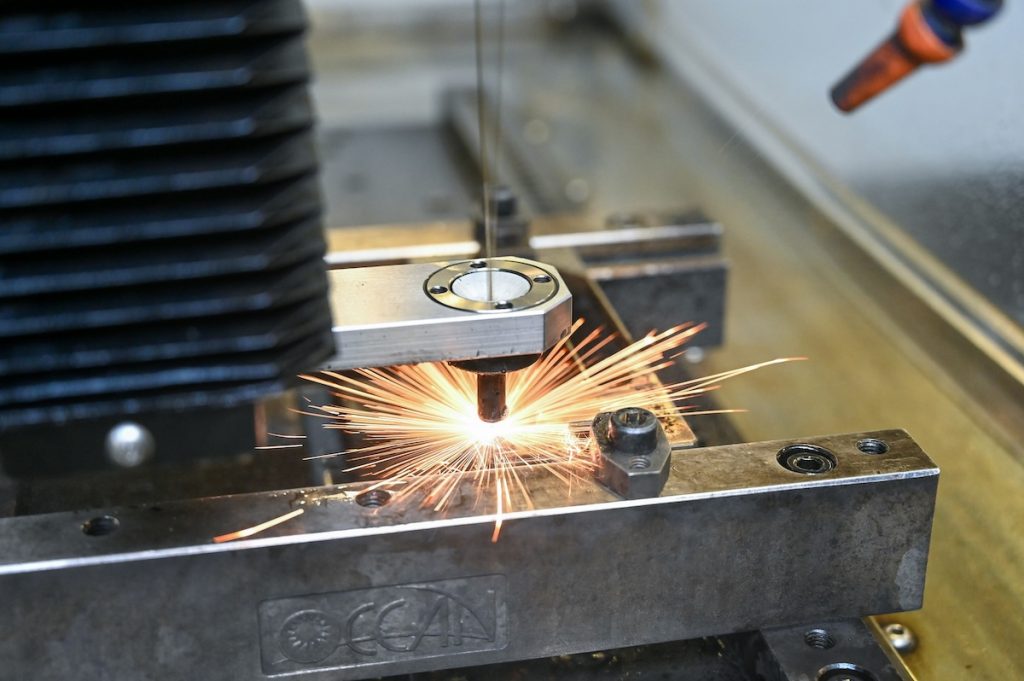

How Laser Cutting Works & Why It Matters for Design

Laser cutting is a subtractive manufacturing process that uses a high-powered laser beam to slice through metal sheets. It offers incredible precision, but even small laser cutting design oversights can impact results.

The process removes material along a narrow path, known as the kerf. Understanding how kerf, heat, and material choice affect your laser cutting design is crucial for getting clean edges, accurate dimensions, and cost-effective parts.

Best Practices & Feature Design Tips

Discover the best practices and laser cutting design tips from experts for all aspects of your project.

Use the Thinnest Material That Can Do the Job

Material cost is often the largest part of your budget. If your laser cutting design allows for a thinner gauge without compromising strength, you can cut faster and more affordably.

Maintain Flatness & Avoid Warp

Flat sheets ensure accurate laser cutting results. Warped or bowed metal leads to alignment issues and inconsistent cuts. Aim for sheet flatness deviations under 0.1 mm per meter.

Keep Safe Distances Between Cut Lines

A good rule of thumb in laser cutting design: the spacing between cut lines should be at least twice the material thickness. This prevents distortion, melting, or accidental bridges that ruin cut quality.

Holes & Bends: Mind the Proximity

Placing holes too close to bends causes deformation. We recommend leaving at least the material thickness (preferably 1.5–2×) between the hole and the bend line in your laser cutting designs.

Allow for Misalignment in Bending

Bending shifts geometry. To compensate:

- Drill holes after bending

- Use slots or oversized holes

- Design jigs or pilot features for alignment

Thread Design Rules

When tapping threads in your laser-cut parts:

- For steel or brass: hole diameter ≤ 2× material thickness

- For aluminum or copper: ≤ 1.5× thickness

This ensures thread strength and avoids stripping.

Maintain Consistent Bend Radii and Orientation

Use a consistent inside bend radius — ideally equal to the material thickness. This improves tooling efficiency, repeatability, and part alignment in your laser cutting design workflow.

Use Standard Sheet Thicknesses & Avoid Too-Small Features

Stick to commonly stocked sheet sizes (1–10 mm for flat parts; 1–6 mm for bent). Avoid tiny features that are smaller than the sheet thickness to minimize distortion or burning.

File & Workflow Guidelines

Getting the most out of laser cutting starts before the machine ever turns on. Clean files, clear part labeling, and surface protection instructions help us cut exactly what you envisioned — without delays or guesswork.

Submit Proper File Formats

DXF or DWG files are ideal. Avoid overlapping paths, and ensure all vectors are closed for accurate laser cutting design execution.

Identify Visual Faces

Call out which side is the “show face” — especially if finish or marking is important to your final part.

Preserve Coated or Sensitive Surfaces

Indicate if certain surfaces need protection from scratches or heat during cutting and handling.

Safety & Process Considerations

Even with advanced tech, laser cutting still demands respect. From choosing safe materials to preventing fires and maintaining equipment, these behind-the-scenes safeguards ensure every cut is clean, consistent, and risk-free.

Material Hazards

Some materials (like PVC) emit toxic fumes. Always check material compatibility before laser cutting.

Fire Safety & Monitoring

Never leave the machine unattended. Keep a fire extinguisher nearby and remove flammable debris.

Maintenance & Alignment

Dirty optics, misaligned beams, or worn-out components cause poor cuts. Routine maintenance ensures top performance and accurate laser cutting design results.

How Eagle Metalcraft Applies These Rules (Your Competitive Edge)

Designing for manufacturability is one thing — having a partner who checks, tests, and improves your parts before they hit the floor is another. Here’s how Eagle Metalcraft adds real value beyond just cutting metal.

Design Reviews Before Cutting

We proactively review your laser cutting designs for spacing, tolerances, and manufacturability. It’s better to catch issues before they hit the floor.

Material Recommendations

Our team often suggests alternate alloys or thicknesses to meet performance needs while saving money.

Test Bends and Prototypes

Need to validate a design before committing? We’ll produce test parts to ensure the real-world fit and function meet your expectations.

Clear Communication

We flag any file issues and confirm everything from bend orientation to finish quality. No surprises.

Laser Cutting FAQ: What Clients Ask Most

We get a lot of great questions from clients — and chances are, you’re wondering the same things. This FAQ clears up common concerns around precision, materials, turnaround, and how to get the cleanest results possible from your laser cutting design.

How precise is laser cutting?

Most cuts are accurate to within ±0.1 mm. Still, tight tolerances should be flagged early so we can adjust our process accordingly.

Which materials can I laser cut?

We cut carbon steel, stainless steel, aluminum, brass, and copper. Have a specialty alloy? We’ll check feasibility.

What’s the thickest material you can cut?

- Carbon steel: up to 25 mm

- Stainless: up to 15 mm

- Aluminum: up to 10 mm

Will there be a heat-affected zone (HAZ)?

Yes, though it’s minimal. Let us know if you have post-processing or welding requirements so we can adjust settings.

Do I need to prepare the file in a certain format?

Yes. Vector files (DXF, DWG, AI) work best. Ensure lines are clean, closed, and labeled for optimal laser cutting design results.

Can I request engraving or part numbering?

Definitely. We can etch part numbers, logos, or guides onto your parts. Just include details in your file.

How fast is the turnaround?

For standard jobs with ready-to-cut files: 3–5 business days. We’ll confirm at the time of the quote.

What if I need help optimizing my design?

That’s our specialty. From hole alignment to material swaps, we’ll work with you to dial in your laser cutting design before it hits the machine.