Printed Circuit Boards, or PCBs, are the unsung heroes behind almost every electronic device we rely on today. Whether you’re scrolling on your phone, driving a modern vehicle, or using a smart appliance, there’s a meticulously engineered PCB inside making everything function smoothly. These boards not only provide mechanical support for components but also serve as the backbone of electrical connectivity, routing signals and power between chips, sensors, and connectors.

Despite their central role in electronics, the processes that go into creating a finished PCB are often misunderstood, especially the difference between PCB fabrication and PCB assembly. Many people, including newcomers to electronics manufacturing, mistakenly think these two terms are interchangeable. In reality, they refer to two completely different stages in the PCB production lifecycle, each requiring specialized equipment, skills, materials, and quality control measures.

PCB fabrication is the process of building the bare board itself—layering materials, etching copper traces, drilling holes, and preparing the surface for components. PCB assembly, by contrast, comes after fabrication and involves mounting and soldering the electronic components onto the board. Both steps are equally essential, and understanding how they differ can save you time, money, and costly production errors.

In this guide, we’ll break down exactly what PCB fabrication and PCB assembly involve, how they complement each other, and what you need to know when planning a project that requires one or both. Whether you’re a design engineer, a product manager, or just curious about how electronics are made, this article will help you confidently navigate the world of PCB production.

What Is PCB Fabrication?

Fabrication is the manufacturing of the bare circuit board without any components. It involves layering materials, patterning copper traces, drilling holes, and applying solder masks and silkscreens. The output is a clean, custom-shaped board ready for electronic assembly.

What is PCB Assembly?

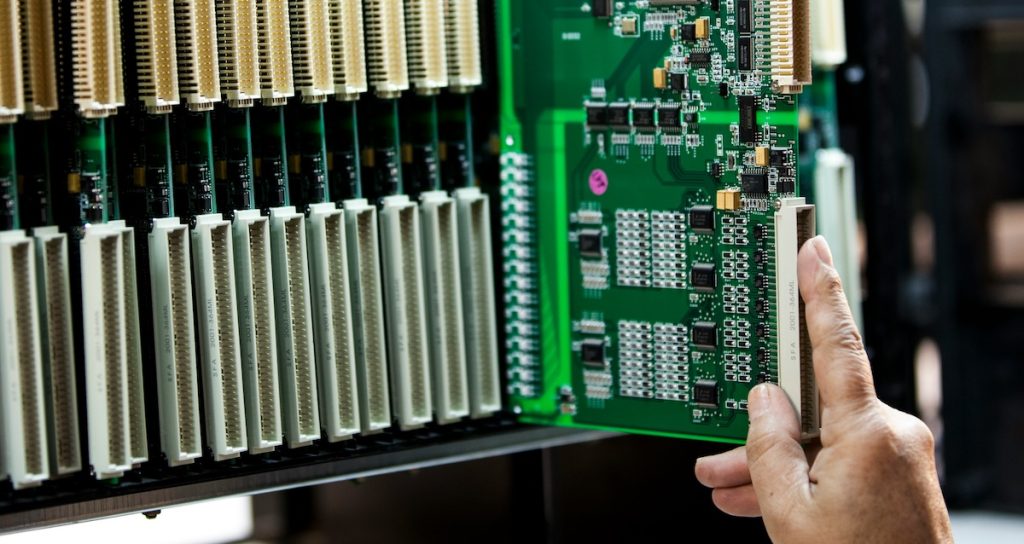

Assembly is the process of placing and soldering electronic components onto the fabricated PCB. This is where the board is transformed from an inert surface into a working circuit. Components are placed with high precision using automation, then soldered and inspected.

PCB Fabrication vs. Assembly: Let’s Look At The Process

Though fabrication and assembly are part of the same product journey, they differ significantly in process. Fabrication builds the structure, while assembly activates it by adding functionality. Both are essential, and neither can replace the other.

Timeframes

Fabrication timelines typically range from three to seven days, depending on board complexity. Assembly may take a similar timeframe, but it largely depends on part availability and order size. Delays in either phase can disrupt project schedules.

Skill Requirements

PCB fabrication demands technical expertise in materials science, chemical processes, and precision machining. PCB assembly, in contrast, requires an understanding of circuit design, soldering methods, and component behavior. Each phase calls for specialized teams and tools to do the job right.

Cost Comparison

Fabrication costs include raw materials, setup fees, and equipment use. Assembly costs involve labor, component procurement, and testing. While fabrication may cost more upfront, assembly becomes more expensive at scale due to recurring material and labor costs.

Common Challenges

Fabrication issues often include misaligned layers or over-etched copper, leading to faulty signal paths. In assembly, errors such as misplacement, cold solder joints, or incorrect parts can lead to failed circuits. Both processes require strict quality control to avoid costly mistakes.

Quality Control Measures

Fabrication quality is verified through electrical tests, AOI scans, and X-rays, especially for multilayer boards. Assembly quality is ensured through functional testing, in-circuit tests, and visual inspections. Rigorous standards are applied at each step to ensure reliability.

How Design Influences Fabrication and Assembly

Design plays a major role in both fabrication and assembly. A poorly designed board may be difficult to fabricate or impossible to assemble without errors. Good design for manufacturability (DFM) and testability (DFT) reduces costs and improves performance.

Gerber Files In PCB Fabrication

Gerber files contain the essential blueprints for fabrication. They include data for each layer, hole placement, and artwork for solder masks and silkscreens. Without accurate Gerber files, no fabrication house can produce the board correctly.

Bill of Materials (BOM) In PCB Assembly

The BOM is a list of every component required to assemble a PCB. It includes part numbers, values, and package types to ensure the right components are used. A clean, complete BOM helps streamline procurement and avoid costly delays.

Turnkey vs. Consigned PCB Assembly

In turnkey assembly, the manufacturer handles both board fabrication and parts sourcing. In consigned assembly, the client provides the components. Turnkey is faster and easier for the client, while consigned offers more control over sourcing.

Trends in Technology

Fabrication is seeing growth in flexible and high-density interconnect boards. Assembly is benefiting from AI-driven automation and smarter inspection tools. These trends are pushing quality and performance to new levels.

Environmental Considerations

Both processes are moving toward greener practices through lead-free solder, chemical recycling, and RoHS compliance. Environmental responsibility now plays a role in how PCBs are produced. Customers are increasingly choosing vendors that offer sustainable options.

Certifications and Industry Standards

Common standards include IPC-A-600 for fabrication and IPC-A-610 for assembly. Certifications like ISO 9001, UL, and RoHS compliance also indicate quality and safety. These standards help ensure consistency and compatibility across global supply chains.

Will You Choose Assembly Or Fabrication?

Fabrication and assembly may sound similar, but they serve different and equally vital roles. One builds the physical framework, while the other activates it with intelligent components. Knowing the difference will help you plan better, avoid missteps, and bring your product to life faster and smarter.

FAQs: Decide Between Fabrication & Assembly

Let’s take a look at the main differences when trying to decide between PCB fabrication and assembly.

What is the main difference between PCB fabrication and PCB assembly?

PCB fabrication is the process of manufacturing the physical board, creating the copper traces, substrate layers, and drill holes. PCB assembly comes after fabrication and involves mounting and soldering the electronic components onto the board to make it functional.

Can I get a PCB assembled without fabricating it first?

No, PCB assembly cannot happen without a fabricated board. Fabrication is the first step, producing the base on which the components are installed during the assembly phase.

Which process takes more time: fabrication or assembly?

It depends on the complexity of the board and the availability of components. Fabrication typically takes 3–7 business days, while assembly can take 1–5 days. Delays in either process can affect your overall timeline.

Is it more cost-effective to do PCB fabrication and assembly together?

Yes, combining fabrication and assembly with one vendor—often called a turnkey service—can save time, reduce costs, and minimize communication errors. It also simplifies quality control and logistics.

What files are required for PCB fabrication and assembly?

For fabrication, you need Gerber files, drill files, and a board outline. For assembly, you’ll also need a Bill of Materials (BOM), pick-and-place file, and assembly drawings. Providing accurate files is essential to avoid costly mistakes.

When should I choose turnkey PCB assembly over consigned assembly?

Turnkey assembly is ideal when you want a hands-off, faster solution where the vendor handles everything. Consigned assembly works best when you want to supply your own components or need full control over sourcing and inventory.