The medical device industry has stringent regulatory requirements that are put in place to ensure the safety, efficacy, and quality of medical devices that are used in various healthcare applications. To navigate these complex regulations and contribute effectively to the sector, companies must prioritize compliance as a fundamental aspect of their operations.

As a cutting-edge precision sheet metal company serving this sector, Eagle Metalcraft places utmost importance on adhering to these regulations to guarantee that our products meet and exceed the required safety and quality standards.

Recognizing the critical role that compliance plays in the medical device industry, we have meticulously integrated a range of comprehensive practices into our operations. These practices serve as the cornerstone of our commitment to meeting the stringent regulatory requirements set forth by relevant authorities.

Key Practices For Compliance ft. Eagle Metalcraft

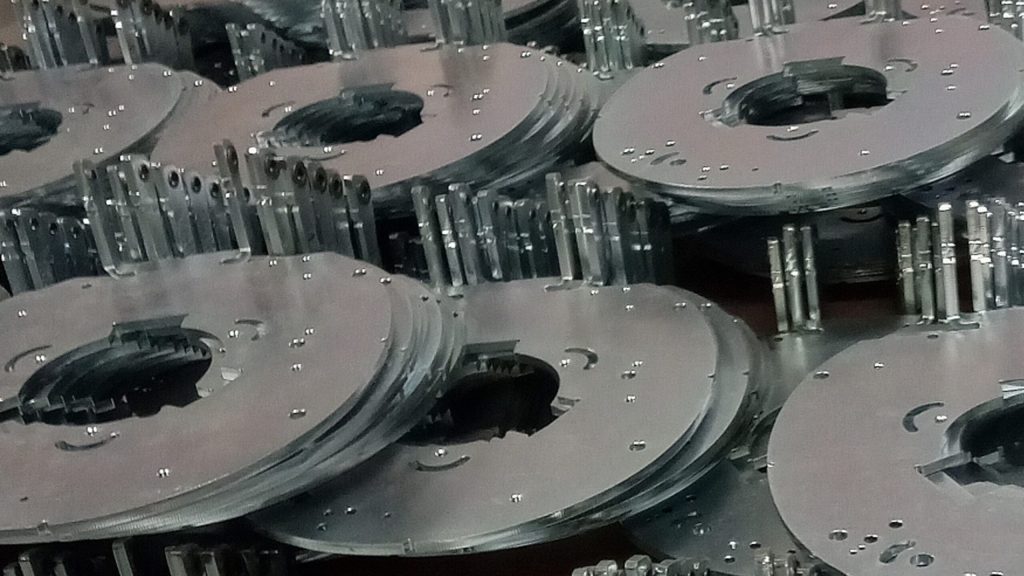

Eagle Metalcraft upholds stringent compliance standards in manufacturing medical devices, ensuring precision and reliability in every component. Our advanced CNC machining and meticulous quality control processes meet the rigorous demands of the medical industry, guaranteeing safety and performance.

Regulatory Expertise and Familiarity

Our team includes experts who are well-versed in the intricacies of medical device regulations. Their knowledge enables us to stay up to date with the latest changes in regulations and standards, ensuring that our products adhere to the most current requirements. We also incorporate specific regulations that apply to medical device manufacturing, including ISO 13485 (medical devices quality management system) and FDA regulations.

Training and Competency

At Eagle Metalcraft, we provide our team with continuous training to ensure they know regulations, quality standards, and best practices. A well-trained, competent staff is essential for maintaining compliance.

Document Control

We maintain meticulous records of our manufacturing and quality control processes. This documentation, which includes design documentation, work instructions, specifications, and records of inspections and tests, ensures transparency and traceability, which are crucial elements for regulatory compliance. These records enable us to demonstrate adherence to regulations and facilitate efficient audits and inspections.

Risk Management Protocols

At Eagle Metalcraft, we conduct thorough risk assessments for each product to identify potential hazards and mitigate risks. This is especially critical in the medical device industry, where patient safety is paramount.

Recognizing the inherent risks associated with medical devices, we employ rigorous risk management protocols throughout our design and manufacturing processes. By conducting comprehensive risk assessments and implementing appropriate risk mitigation strategies, we mitigate potential hazards and enhance the overall safety profile of our products.

Quality Management System (QMS)

We have implemented a robust quality management system (QMS) that aligns with internationally recognized medical device industry standards such as ISO 13485. This system covers all aspects of the manufacturing process, from design and development to production and post-production activities.

Our QMS framework provides a structured approach to quality assurance, risk management, and regulatory compliance, ensuring that our products consistently meet the highest safety and performance standards.

Validation and Verification

Our team validates and verifies all processes, equipment, and software used in our manufacturing process, ensuring they perform as intended, which allows us to meet regulatory requirements.

Change Management and Non-Conformance Management

We have established a well-defined change management process to assess and document any changes made to products, processes, or materials. This helps prevent unintended consequences on quality and compliance.

We have also developed and implemented a process for handling non-conforming products or processes. This includes investigation, root cause analysis, corrective actions, and preventive measures.

Traceability and Supplier Audits

We have implemented systems for the traceability of materials and components used in our products. This is vital for tracking the origin and journey of each part, which is essential in case of recalls or quality issues.

Additionally, we regularly audit and evaluate our suppliers to ensure they also adhere to regulatory standards. This applies to both the raw materials and any outsourced processes.

Collaboration with Regulatory Authorities and External Audits

We actively engage with regulatory authorities to gain insights into evolving regulatory landscapes. This proactive collaboration allows us to anticipate changes, adapt our processes accordingly, and maintain a competitive edge in an ever-changing industry.

We also regularly undergo external audits by certification bodies, customers, or regulatory agencies to ensure our compliance efforts are robust and effective.

Validation of Processes and Equipment

Before our products reach the market, they undergo rigorous validation and verification processes. These tests ensure that our devices perform reliably, accurately, and consistently per the intended use and regulatory expectations, which is critical in the medical device industry.

Inspection and Testing

At Eagle Metalcraft, we have implemented stringent inspection and testing protocols for products. This includes both in-process inspections and final product testing to ensure medical devices meet required specifications.

Continuous Improvement

As a leader in the precision sheet metal industry, we have implemented a culture of continuous improvement, utilizing methods like Six Sigma or Lean, to identify and address areas for enhancement in compliance, quality, and efficiency. Our commitment to regulatory compliance extends beyond initial product development.

We continually evaluate and enhance our processes based on post-market feedback, audits, and lessons learned, ensuring that our products remain in compliance throughout their lifecycle.

Dedication To Compliance Is Key

At Eagle Metalcraft, maintaining compliance is an ongoing effort that we embrace with vigilance and dedication. We are deeply dedicated to upholding the highest safety, efficacy, and quality standards in the medical device industry.

Incorporating these practices demonstrates our unwavering commitment to meeting and exceeding the stringent regulatory requirements governing this vital sector. By consistently embracing compliance, we contribute to the advancement of healthcare technologies and the well-being of patients worldwide.

FAQs

Compliance in the medical device industry isn’t just a requirement—it’s a responsibility. At Eagle Metalcraft, we’ve embedded compliance into the core of our operations, aligning with strict industry standards like ISO 13485 and FDA regulations.

From quality systems to risk management and traceability, our practices ensure the safety, performance, and regulatory readiness of every component we produce. This FAQ offers insight into the key measures we’ve implemented to serve the medical sector with precision and integrity.

Why is regulatory compliance important in the medical device industry?

Regulatory compliance ensures the safety, efficacy, and quality of medical devices. In such a highly regulated industry, manufacturers must meet strict standards to protect patients and maintain trust with healthcare providers and regulatory bodies.

What regulations and standards does Eagle Metalcraft follow?

We adhere to ISO 13485 for quality management in medical devices and meet FDA regulatory requirements. Our team stays current with evolving standards to ensure our products consistently meet the latest expectations.

How does Eagle Metalcraft ensure team competency in compliance matters?

We provide ongoing training to our employees on relevant regulations, best practices, and quality standards. This continuous education ensures our team remains knowledgeable and capable of upholding strict compliance expectations.

How is risk managed in the manufacturing process?

We conduct comprehensive risk assessments to identify, evaluate, and mitigate potential hazards. This approach is critical in the medical field, where patient safety is paramount. Our protocols ensure risks are addressed proactively at every stage.

What kind of quality management system (QMS) is in place?

Our QMS aligns with ISO 13485 and governs all phases of product development—from concept to post-production. It ensures consistent quality, regulatory compliance, and continuous improvement throughout our operations.

What is validation and verification, and why is it important?

We validate all processes, equipment, and software to confirm they function as intended. Verification ensures that final products meet defined specifications. These steps are essential for regulatory approval and product reliability.

What is the role of traceability in medical device manufacturing?

Traceability allows us to track every component and material used in our products. This is essential for managing recalls, resolving quality issues, and maintaining regulatory compliance throughout the product’s lifecycle.

How are suppliers monitored for compliance?

We regularly audit and evaluate our suppliers to ensure they meet regulatory standards. This includes both raw material providers and partners involved in outsourced processes.

How are medical device components tested and inspected?

Our inspection protocols include both in-process and final testing. These steps ensure that each product meets exact specifications before it leaves our facility.